Windows & Doors

The History of Steel Windows

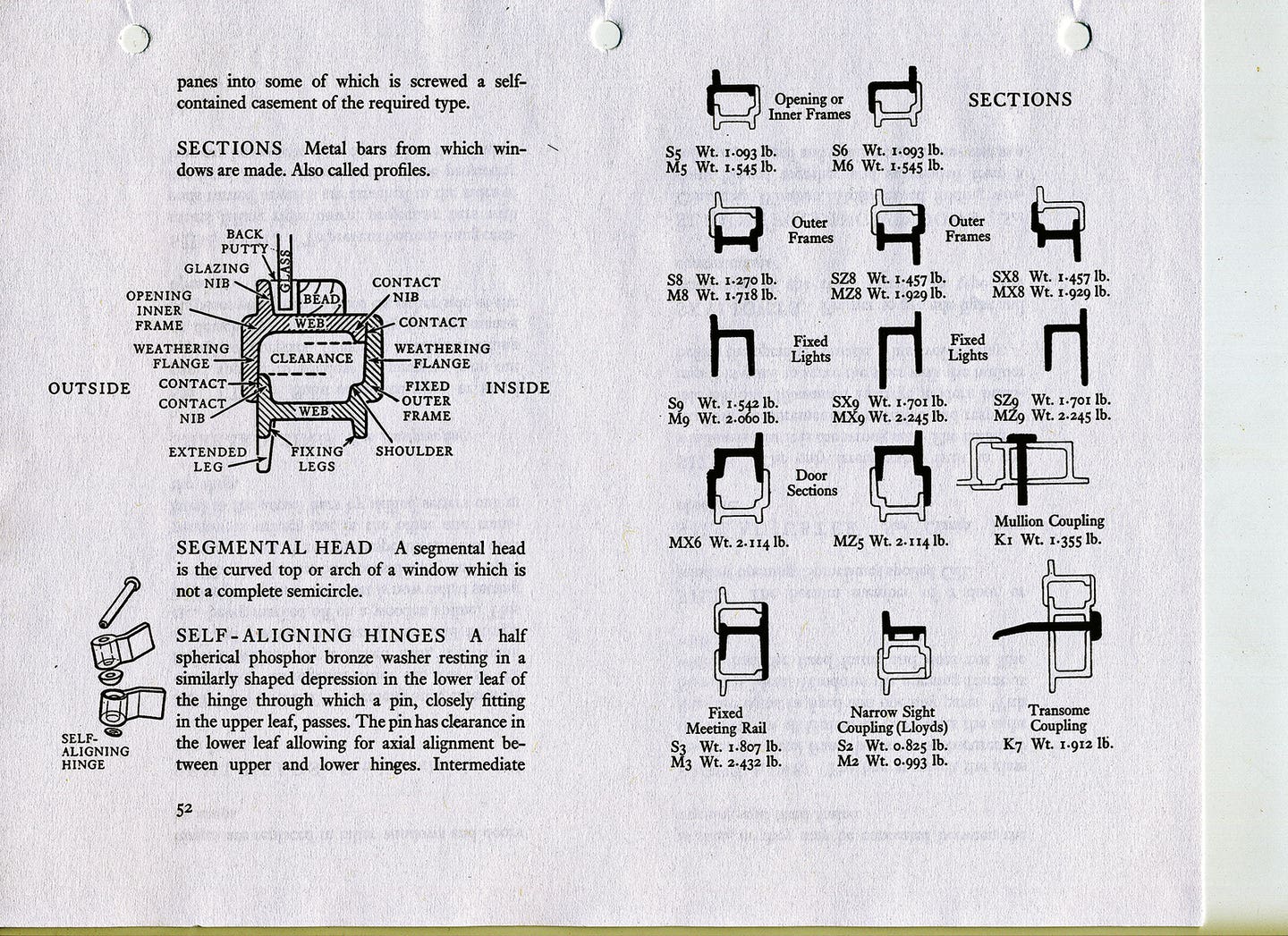

Steel windows are built from bars of various profiles that are produced in rolling mills by passing lengths of hot steel through pairs of rolls, a process also used to make I-beams and railroad rails. “Back through the ‘20s, ‘30s, and ’40s, when steel windows were used all the time, there were over 100 different profiles available,” explains Darren Joyce of Crittall Windows, Ltd. in Witham, UK. Nonetheless, between 1912 and 1964, the most prolific steel window section was called the Universal Range of profiles, with a small, medium, and large Universal Range. “This was a world-wide system available to many window manufacturers at the time, not just the largest, such as our company.”

After 1940 when aluminum windows and then vinyl windows came in, the rolling mills couldn’t economically produce the numerous profiles in smaller quantities. “So in 1964 and they took the best bits of all the profiles and rationalized them down into what is called the W20 profile, which is in the same family, so to speak of the original Universal Range profiles. This too is a product open to all and the most common steel window profile in use today.”

At the same time mills produced the SMW (Standard Metal Window) range, which became available in 1919 and was used for residential and light commercial windows. Joyce says SMW was among the most widely used profiles in the world. “You’ll see SMW windows everywhere in nearly all countries worldwide, and it is still available today, untouched, with no changes to the profile at all.”

Custom fabricator & installer of architectural cladding systems: columns, capitals, balustrades, commercial building façades & storefronts; natural stone, tile & terra cotta; commercial, institutional & religious buildings.