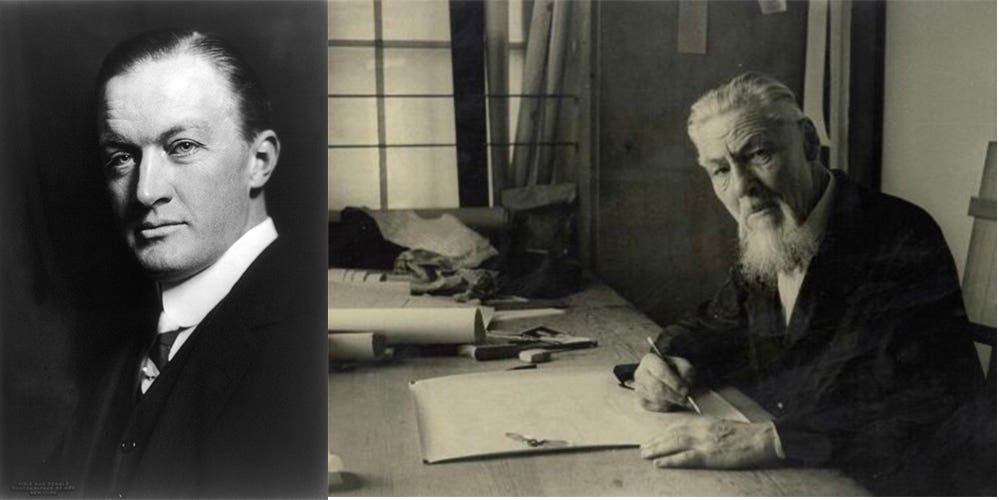

Peter Miller

Claiming Your Profit

I was standing at baggage claim, waiting 45 minutes before I could lug my suitcase off the belt. It seemed like an awfully long time to wait, especially after I’d paid 25 bucks to check my bag. Then I got to thinking: “Hey, with fuel prices way down, why are the airlines charging for checked baggage?”

Pay more, get less. As I waited, my annoyance grew. Is it because of discounting and transparency in ticket prices that airlines are forced to scrounge for profits—even if their customers think it unfair? Is this trend unique to the airlines, or is it an epidemic in our rebounding economy?

Profit margins are what we all think about but rarely discuss. Despite three years of rising revenues in homebuilding and remodeling, profit margins haven’t come back to pre-recession levels. In fact, most homebuilders I talk to have lost five margin points, from about 20% to 15%, sometimes even less, depending on job size. This makes our margin of error very slim. What’s going on? And what practices might improve profitability?

A HARDER SELL

Homebuyers and major-remodeling clients are more demanding and take longer to make up their minds. They want to control the process. If they are building a $5 million house, they are likely spending $8–10 million all in, with land, landscaping, and furniture. That’s a lot of money. Clients are looking to save somewhere in order to get the house they want. Their line-by-line scrutiny is assured. For the client building a $1.5 million house, scrutiny is likely even more intense.

Even as homebuilders sharpen the pencil just to get the work, their costs keep going up—due to material prices and the scarcity of labor, for sure, but most of all, due to “the cost of doing business” in a professional way. Insurance, workers’ comp, wages, health care, jobsite safety and security … you name it, all overhead expenses are up. The builder bidding against you is telling prospects, “I’m a small business. You won’t pay me a lot for overhead.” He’s telling your clients that your overhead is too high, and they believe it.

Builders tell me that consumers have “exaggerated expectations,” that they want a $1.5 million custom home for $1 million. This is certainly true of the homebuyer research we do. Before the recession, clients were happy to get on the builder’s schedule to get a house built quickly. Now, it’s about the money, perceived value, getting the best deal, building a legacy house. If the builder gives up his profit, the client won’t have to give up the granite countertops.

THE OVERHEAD EQUATION

Builder business consultant Mark Richardson, himself a former high-end, whole-house remodeler, points out that “overhead eats profit.” Inefficiencies can usually be found in a builder’s internal operations. Clients do not want to pay for inefficiency—yet this is where builders can save, by tighter management, elimination of mistakes, better personnel, low employee turnover, and time-saving techniques and technology. Richardson says, “We must control the controller … manage our own processes, even though the client wants to be in control.” He also cites “more choices,” which take more time and more hand-holding, cutting further into margins.

If managing overhead is the key to improving profits, how do we do that? Richardson likens overhead management to physical fitness. “Take a holistic approach,” he argues. “Help make your people better at their jobs.” In my own business, several years ago, I found $750,000 in cost savings by asking each of my major suppliers to help me find 10% savings. I was stunned at how much I learned, from suppliers, how to be more cost efficient.

“Time is money and everything takes longer now, even ordering materials, which are not stocked in inventory now,” says Rich Wilkinson, a Nashville homebuilder. “To order building materials, we have to plan way ahead to save money, yet the client is hard to pin down that far in advance.”

EDUCATING THE CLIENT

Joe Bohm of Horizon Builders, Builder of the Year, tells me that “clients do not necessarily recognize good quality.” Convincing them to pay for quality, including superior project management, is always a challenge. “When we are building a $7 million house, a lot goes into it: labor, materials, financing, time management, personnel management, and client service. It’s like running a $7 million business. Who would you want running your $7 million company?” Bohm asks rhetorically. We agreed, it’s a builder who manages well and gets paid, fairly, to do so.

“Our best subcontractors are overbooked with work,” Ft. Worth custom builder Brent Hull explains. “So sometimes we have to go to our B team subs to get the work done on time.” This, too, I noted, can cost money in mistakes. But Hull’s job sizes are getting bigger and he is maintaining margins with houses ranging from $4 to 10 million. Nonetheless, Hull says, “our clients are all trying to make good-value decisions, but price is a big issue.”

Horizon Builders sells value to clients by educating them on the “Four Pillars.” Bohm says, “When you walk into a new house, what you see is the paint. We talk about what’s underneath the paint, like SAFETY (good engineering); HEALTH (water resilience and mold retardant materials); COMFORT (geo-thermal systems); and CRAFTSMANSHIP (the quality of Horizon’s building suppliers).” Every builder agrees that the client must be schooled on what real quality home building is, and why it costs what it does. We should get paid not just for what we do but also for what we know.

Horizon Builders “Four Pillars” pitch tells clients about the quality of the new house, and also about the quality of their homebuilding management experience. Listening to Joe Bohm, I was struck by this contradiction: the same well-heeled client who invests his money in well-managed public companies is reticent to pay for his own well-managed building project! The same attorney who bills by the hour does not want to pay for the builder’s time.

“When we give a prospective client references, we give them past clients who have lived in the house we built for at least ten years,” Bohm insists. “That way, our references can speak to the longer-term comfort, quality, and performance of our homes.”

COST MANAGEMENT

I spoke to several builders who charge a flat fee of 10% on construction cost as their management fee. They tell the client about this upfront and then manage job cost to the client’s advantage. “We look out for our clients,” states Dan Mitchell of Eagle Construction in Knoxville. “Our clients know upfront we are going to make a profit and that’s OK. We show them every material invoice and job cost with total transparency.”

In Northeast markets, builders’ fees are higher: 18% on jobs under $2 million; 16% for jobs above $ 2 million; a sliding scale downward as jobs get really big. The time-and-materials contract is preferred, but requires a level of communication and paperwork that can be daunting to both builder and client.

Connecticut custom homebuilder Tim Hine acknowledges that clients are more demanding. But he has several disciplined business practices that keep his projects organized, save time in processes, and lead to better profitability. “We have a full-time person in the office who works on pricing and quotes. We do thorough research on material costs and stay ahead of clients’ questions. Our clients always want options, so we research those options in advance, which helps us control the selection process and save time.”

In very high-end custom building and remodeling, products may be exotic, including imported materials. Hine advises, “Unusual products take time to find and can have extra costs. We research this carefully to make sure we are getting the best price for our clients. We would rather buy locally, but sometimes we find better prices online.”

Also at play in high-end jobs is the duration of project, often two years or longer. “Before we go to contract on a new project, we look at all our expenses to be sure we are not locking ourselves into something that will hurt us at the end,” says Hine.

Value engineering, a recession-era euphemism for “cut your price please,” is now pretty commonplace on big residential jobs. Tim Hine tells me that “VE takes place on every job, every day.” The time it takes costs money. So streamlining paperwork, getting clean and accurate bills from subcontractors, and keeping careful records of material purchases are all important time and cost savers.

“Project teamwork is particularly important,” says Hine. “When the builder, architect, interior designer, and subs are on the same page, the project goes smoothly and cost is controlled.” Joe Bohm agrees: “Builder, architect, and client teamwork are critical to a project’s success.”

Peter H. Miller, Hon. AIA, is the publisher and President of TRADITIONAL BUILDING, PERIOD HOMES and the Traditional Building Conference Series, and podcast host for Building Tradition, Active Interest Media's business to business media platform. AIM also publishes OLD HOUSE JOURNAL; NEW OLD HOUSE; FINE HOMEBUILDING; ARTS and CRAFTS HOMES; TIMBER HOME LIVING; ARTISAN HOMES; FINE GARDENING and HORTICULTURE. The Home Group integrated media portfolio serves over 50 million architects, builders, craftspeople, interior designers, building owners, homeowners and home buyers.

Pete lives in a classic Sears house, a Craftsman-style Four Square built in 1924, which he has lovingly restored over a period of 30 years. Resting on a bluff near the Potomac River in Washington, D.C., just four miles from the White House, Pete’s home is part of the Palisades neighborhood, which used to be a summer retreat for the District’s over-heated denizens.

Before joining Active Interest Media (AIM), Pete co-founded Restore Media in 2000 which was sold to AIM in 2012. Before this, Pete spent 17 years at trade publishing giant Hanley Wood, where he helped launch the Remodeling Show, the first trade conference and exhibition aimed at the business needs and interests of professional remodeling contractors. He was also publisher of Hanley Wood’s Remodeling, Custom Home, and Kitchen and Bath Showroom magazines and was the creator of Remodeling’s Big 50 Conference (now called the Leadership Conference).

Pete participates actively with the American Institute of Architects’ Historic Resources Committee and also serves as President of the Washington Mid Atlantic Chapter of the Institute of Classical Architecture & Art. He is a long-time member of the National Trust for Historic Preservation and an enthusiastic advocate for urbanism, the revitalization of historic neighborhoods and the benefits of sustainability, including the adaptive reuse of historic buildings.

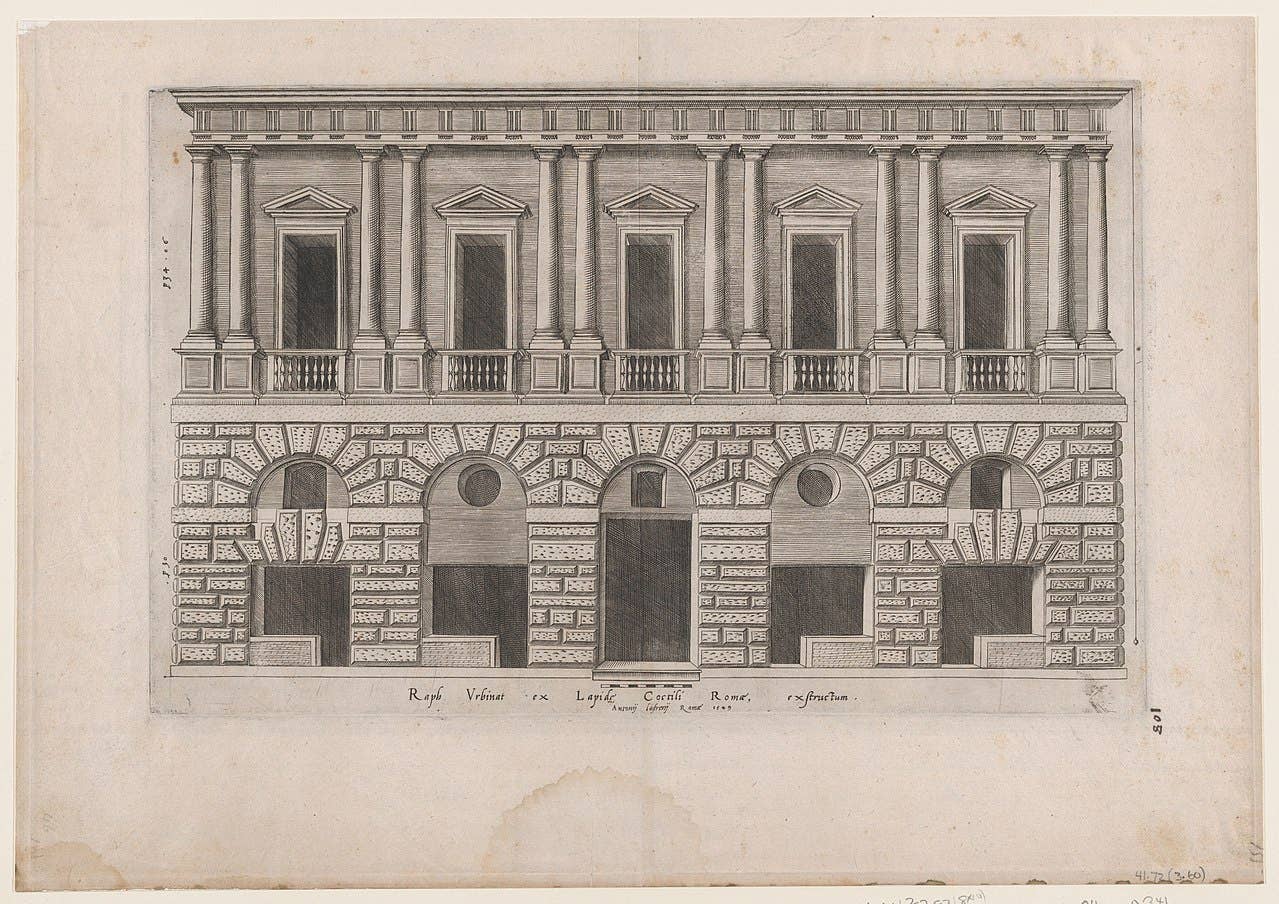

Custom fabricator & installer of architectural cladding systems: columns, capitals, balustrades, commercial building façades & storefronts; natural stone, tile & terra cotta; commercial, institutional & religious buildings.